Epoxy Coated Rebar (ECR) versus Fiberglass Rebar (GFRP)

Once the epoxy is encased in concrete, water and chloride vapors, liquids seep under the paint film thru any crack, pinhole, sheared end, scuff caused during handling.

Once the epoxy is encased in concrete water and chloride vapors and liquids seep under the paint film thru cracks, pinholes, sheared ends and scuffs caused during handling.

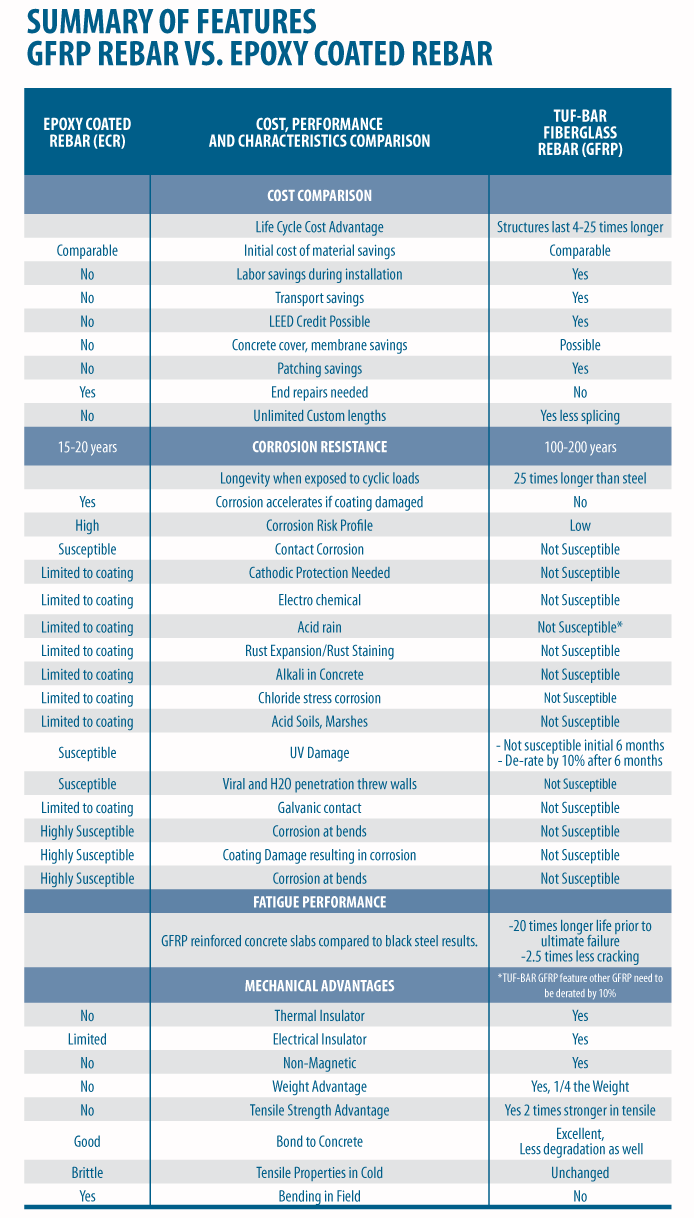

Epoxy Coated Steel Re-bar (ECR) is comparable in price to GFRP and the coating on epoxy re-bar has proven to slow down the corrosion process on steel if it remains intact. Maintaining the integrity of the coating is difficult to ensure during the process of manufacturing and even more difficult to maintain at a construction site.

A pinhole manufacturing defect or a scratch that may occur during handling or placement at a construction site will cause an epoxy coated rebar to degrade rapidly.

Epoxy coated rebar has been banned in the province of Quebec. Other provinces in Canada and many U.S. States have initiated studies re-evaluating its use.

The performance of epoxy coated reinforcement:

Experience of the Ontario Ministry of Transportation

Volume 23, Number 3-4/2005

http://inderscience.metapress.com/link.asp?id=770h0×2qayqrv443

Abstract:

The Ontario Ministry of Transportation has a mandate to specify cost-effective methods and materials for the construction and maintenance of provincial highway structures. In support of this mandate, the Bridge Durability Work Group initiated a performance evaluation of epoxy-coated reinforcement (ECR) in the Ontario

The Ontario Ministry of Transportation has a mandate to specify cost-effective methods and materials for the construction and maintenance of provincial highway structures. In support of this mandate, the Bridge Durability Work Group initiated a performance evaluation of epoxy-coated reinforcement (ECR) in the Ontario bridge environment. Findings of the investigation, which are summarized in this paper, strongly indicate that the long-term performance of the ECR is not likely to provide the corrosion resistance or associated maintenance free service life that was originally forecast. Several Ministry structures constructed with ECR have already been rehabilitated, before achieving even a 20-year service life. Today, the Ministry must develop and adopt strategies at the time of design for service life that far exceed the expectations of only a few years ago; typically, in accordance with the new Canadian Highway Bridge Design Code, the design life of new structures is anticipated to be 75 years. A significant body of research to date indicates that ECR can at best provide marginally longer service life than black reinforcement.

Epoxy coated reinforcement study

Final report state research project #527

Oregon Ministry of Transport Studies conclusion:

“Therefore, the continued use of this type of reinforcement in coastal structures in Oregon is not recommended. It is recommended that existing coastal structures and structures subject to de-icing chemicals that are reinforced with epoxy coated steel be placed on a frequent inspection program.”

Click here for full copy of the Oregon Ministry of Transport Study:

http://www.cobrae.org/htmlfolder/papers/generalepoxyrebar-oregon.pdf

Final Contract Report

Corrosion protection service life of Epoxy-Coated Reinforcing Steel (ECR) in Virginia bridge decks.

It is apparent that at least some of the existing Epoxy-Coated steel re-bar (ECR) decks in service will not achieve the anticipated design life. Repair procedures and remediation strategies must be specifically developed to address ECR. Some procedures, such as cathodic protection, may not be successfully implemented in such structures. Removing chloride contaminated concrete and installing overlays above ECR that has initiated corrosion may prove insufficient, since corrosion beneath the coating may progress under completely different mechanisms once initiated.

Florida DOT study –marine applications

Laboratory tests and field inspections indicate that epoxy-coated rebar in a marine substructure application is more susceptible to corrosion than bare bar. The underlying clean bright metal, which does not passivate, as does bare steel when in contact with cement, is highly susceptible to corrosion.

Epoxy-coated rebar has deteriorated faster than bare steel. While bare steel actively corrodes in marine environments (12-15) years) the epoxy-coated rebar has begun to corrode much earlier in these structures (seven to nine years)

Natural Sciences and Engineering – Research Council of Canada

www.nserc-crsng.gc.ca

2009 Abstract: Concrete Structures Last Four Times Longer

Results from Fiberglass Reinforced Bridges in Canada

The Chair’s researchers have conducted field tests on more than 10 bridges across Canada… FRP materials can be preserved for 100 years or more. By contrast, steel-reinforced concrete will begin to deteriorate after 10 to 15 years and will generally require major repairs after 25 years.

Durability of Fiber Reinforced Polymers in Civil Infrastructure

22 Researchers, 4 Universities

http://www.isiscanada.com/news/durability.html

2008 Abstract: This study reviewed 5 Canadian bridges and 1 Canadian harbour that were constructed in the early 1990’s. All structures were exposed to harsh environmental conditions. Longevity of concrete reinforced with fiberglass rebar (GFRP) was extensively studied. The longevity conclusions from the studies contributed to the adoption of GFRP as an approved reinforcement for Canadian and American Civil Structures.

Conclusion from Field Studies

- No evidence of de-bonding between GFRP and concrete in any structure.

- Alkali attack could not be detected in the GFRP reinforcement materials.

- No deterioration of GFRP reinforcement took place in any of the field demonstration structures.

- Studies indicate GFRP reinforcement degrades very slowly in concrete. Corrosion rates indicate the reinforcement has a viable life of over 160 year.