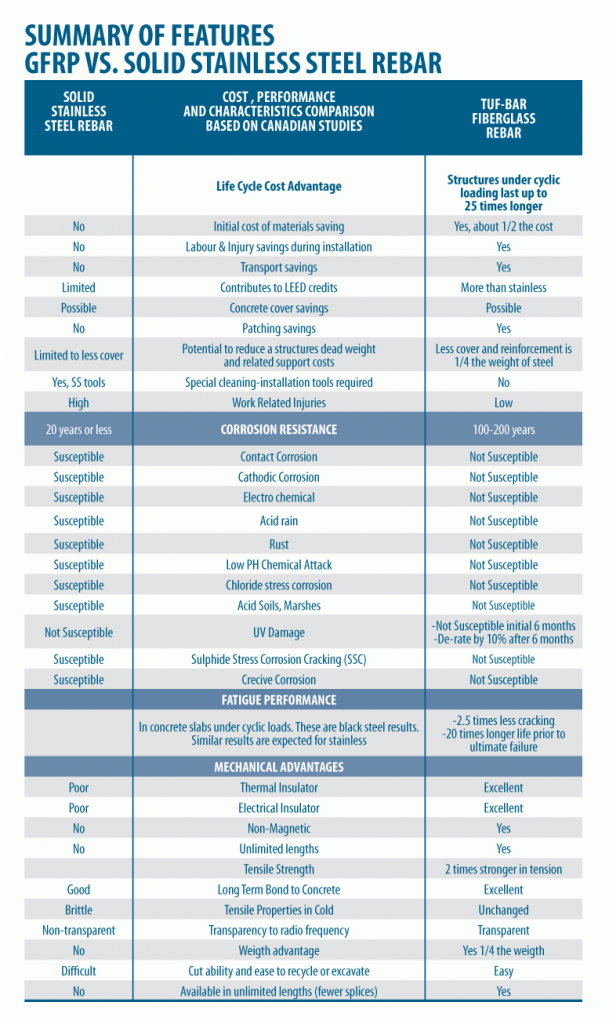

Stainless Steel Versus Fiberglass Rebar (GFRP)

Corrosion Effect

Stainless steel as all other metals (except gold) rust. Bridge deck studies indicate that it will last longer than other types of steel reinforcement in the right environment.

Once the corrosion cycle begins the corrosion cycle of steel rebar takes over and the concrete is eventually destroyed.

Stainless steel’s initial cost is much higher than fiberglass rebar or other types of steel reinforcement.

GFRP’s initial cost is less, it will last longer and it will create less concrete damage and repair costs over time.

13 year old swimming pool in Switzerland collapsed after failure of stainless steel rods due to chloride induced corrosion.

Stainless Steel Corrosion Issues

Sulphide Stress Corrosion Cracking (SSC)

http://www.azom.com/details.asp?articleID=1177 – _Stress_Corrosion_Cracking

Fiberglass rebar and fasteners eliminate sulphide stress corrosion cracking and are ideal use for use in oil and gas applications.

Stress corrosion cracking (SCC) is the cracking induced from the combined influence of tensile stress and a corrosive environment. The impact of SCC on a material usually falls between dry cracking and the fatigue threshold of that material. The required tensile stresses may be in the form of directly applied stresses or in the form of residual stresses (see an example of SCC on an aircraft component). Buried pipelines provide a good example of such complexity. The impact of such stress corrosion cracking is most commonly catastrophic as exampled by the historical failure of the UK Flixborough chemical reactor in 1974.

Fatigue Effect

Bridge deck studies simulating heavy traffic going over concrete slabs have concluded that properly reinforced GFRP fiberglass rebar slabs experience:

- Experience 2.5 times less cracking than steel reinforced slabs

- Last 20 times longer than steel reinforced slabs when exposed to heavy fatigue loads

Researchers believe that this is due to the differences in the modulus of elasticity between GFRP and steel. GFRP has a modulus very similar to concrete. Steel’s modulus is many times higher. Steel is less forgiving than GFRP. Damage occurs to concrete as steel bends within the pour.

Corrosion Fatigue

http://corrosion-doctors.org/Forms-fatigue/fatigue.htm

Fiberglass rebar does not experience mechanical or corrosion fatigue in the same way as steel. When exposed to cyclic loads, no micro-cracking has been detected.

Crevice Corrosion

http://www.alberg30.org/maintenance/Steering/CreviceCorrosion/

Fiberglass rebar and fasteners are immune to crevice corrosion and have been used in floating dock and other applications where corrosion is an issue.

Contact Corrosion and Galvanic Corrosion.

Galvanic corrosion will occur if stainless steel bar comes into contact other types of steel. GFRP is an electrical insulator… without an electrical pathway between different types of steel no corrosion will occur.

Carbon steel contamination has no effect on Fiberglass rebar. Stainless steel rebar tools are not required for installation. Fiberglass rebar eliminates potentially time consuming and health hazardous acid pickling solutions required to clean stainless steel rebar.

Chloride Induced Stress Corrosion

Lack of chloride resistance in stainless steel has lead to rapid degradation of reinforcement in some applications. Rebar chloride resistance is listed below:

- Carbon rebar steel can only tolerate chloride levels of 0 – 0.4%.

- Stainless steel rebar can tolerate chloride levels up to 7%.

- GFRP fiberglass rebar can tolerate chloride levels up to 100%

“Stainless steel as all other metals (except gold) rust”